When you buy a pill, a medical device, or even a children’s toy made overseas, you assume it’s safe. But in 2025, that assumption is riskier than ever. Foreign manufacturing quality issues aren’t just about slightly off-color packaging or a loose screw-they’re about contaminated medicines, toxic materials in medical devices, and entire batches of life-saving drugs being recalled because no one was watching. The problem isn’t getting better. It’s getting worse.

Why Quality Is Falling Apart Overseas

The shift to overseas production was supposed to save money. And for a while, it did. But as labor costs rose and profit margins shrank, many factories cut corners. Today, the biggest threats aren’t accidental mistakes-they’re deliberate. In China, 68% of inspected pharmaceutical facilities have been caught substituting cheaper, unsafe materials for approved ones. One facility replaced medical-grade silicone with industrial-grade plastic in breathing devices. Twelve thousand units were shipped before anyone noticed. The result? A recall, a lawsuit, and a brand that took years to recover. It’s not just China. Indian manufacturers accounted for 34% of all FDA drug import alerts in 2024, even though they only make up a quarter of foreign production. In Vietnam, quality has improved since 2022, but many suppliers still lack the systems to catch defects early. The problem isn’t location-it’s oversight. Too many companies rely on third-party inspectors who show up on schedule, giving factories time to clean up. The FDA found that 78% of inspections in China were announced in advance. In the U.S., only 5% were. That’s not a coincidence. It’s a loophole.The Hidden Cost of Cheap Production

You think you’re saving 30-45% on labor by manufacturing overseas. But when a batch fails, the real cost kicks in. Rework. Shipping returns. Legal fees. Lost trust. Harris Sliwoski’s 2025 analysis shows unaddressed quality issues add 15-25% to total manufacturing costs. That’s not a savings. That’s a loss disguised as efficiency. And it’s not just money. The FDA linked foreign manufacturing failures to 37% of U.S. drug shortages in 2024. Imagine needing a heart medication and your pharmacy says it’s out of stock-not because of supply chain delays, but because the batch from a factory in Wuhan had too many impurities. That’s not a supply issue. That’s a safety failure.How Factories Cheat and How to Catch Them

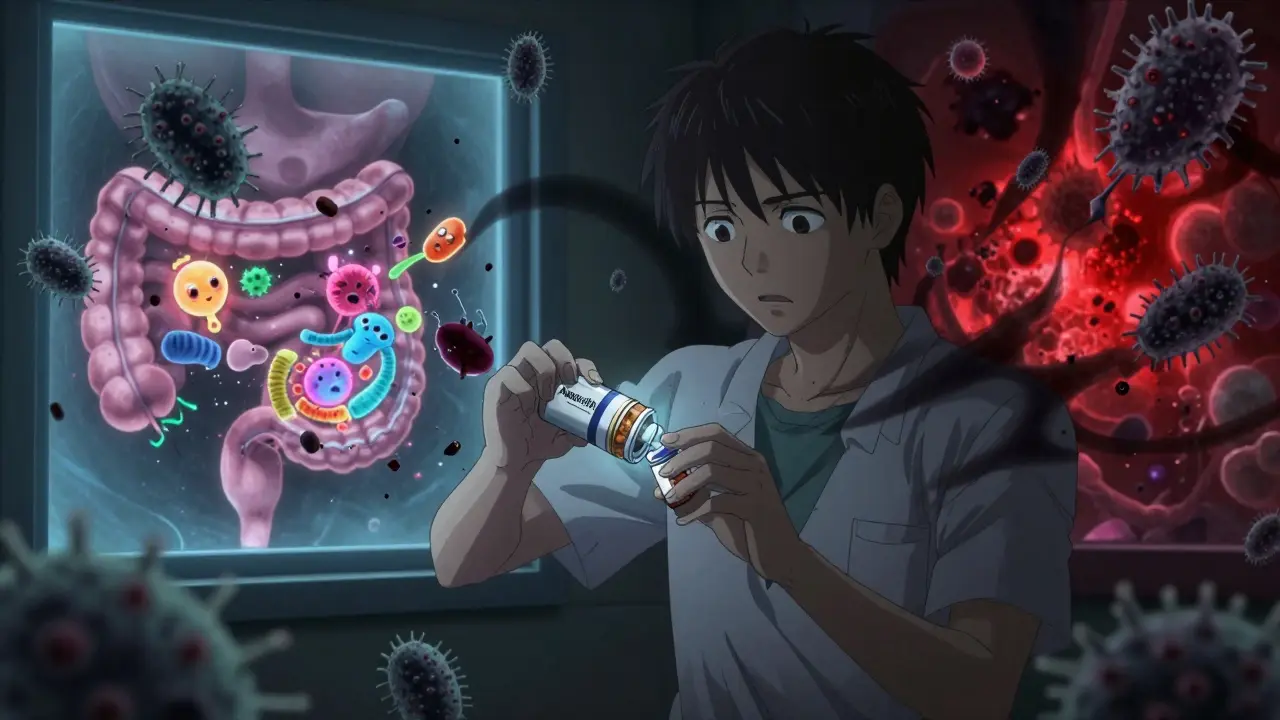

Here’s how it works: A factory gets an order for 100,000 insulin pens. They know the client won’t test every unit. So they use a cheaper plastic for the casing. They skip a sterilization step. They fake the lab reports. And when the inspector shows up? They pull out the good samples from a separate, clean room. It’s called a “showroom factory.” Traditional inspections won’t catch this. But AI-powered visual inspection systems can. These systems scan products at 1,000 frames per second, spotting microscopic flaws humans miss. They detect missing components, wrong labels, even color shifts in materials. According to GQC.io’s 2025 survey, AI detects defects at 99.2% accuracy. The problem? Only 22% of Chinese factories have adopted them. The solution isn’t just tech-it’s structure. Successful companies use what’s called a “China-specific quality triad”: a local quality manager who reports directly to headquarters, blockchain-based traceability so every batch can be tracked back to its raw materials, and third-party audits done without notice. One Minnesota medical device company cut defects from 12.7% to 0.8% in two years using this model.

The Regulatory Shift: What’s Changing in 2025

The FDA is no longer playing along. On May 6, 2025, Commissioner Marty Makary announced a new policy: parity inspections. That means foreign facilities will be inspected the same way U.S. ones are-no advance notice, no special treatment. By the end of 2025, 40% of foreign inspections will be unannounced. By 2027, that number jumps to 75%. This is huge. For years, factories in China knew when inspectors were coming. Now, they don’t. The result? A spike in compliance reports. One facility in Chengdu was shut down after inspectors found falsified temperature logs for vaccine storage. Another in Shanghai had to recall 80,000 units after AI scanning detected inconsistent coating thickness on pills. Meanwhile, the EU’s Qualified Person (QP) system is gaining attention. Every batch of medicine shipped into the EU must be signed off by a licensed professional based in Europe. That person is personally liable if something goes wrong. It’s not perfect, but it’s forced accountability. U.S. regulators are now considering a similar model.What You Need to Do Now

If you’re sourcing products overseas, here’s what you can’t ignore:- Don’t trust the supplier’s word. Demand access to raw material certificates, batch test results, and audit logs. If they say no, walk away.

- Require unannounced audits. Your contract must state you can show up anytime-with or without notice. And you must have the right to take samples.

- Use local quality staff. Hire someone on the ground who answers to you, not the factory manager. Pay them directly. Give them authority to halt production.

- Invest in traceability. Blockchain or QR-based tracking isn’t fancy-it’s necessary. If a batch fails, you need to know exactly where every component came from.

- Train your team. Companies that spend $18,500 per year per facility on quality training see 33% fewer defects. That’s not an expense. It’s insurance.

The Bigger Picture: Friend-Shoring and the Future

More companies are moving production to allied countries-Mexico, Vietnam, Poland. It’s called “friend-shoring.” But this isn’t a magic fix. New suppliers often have weaker systems. A factory in Mexico might not know FDA standards. A plant in Poland might lack trained inspectors. The quality gap doesn’t disappear-it just moves. The real winners will be the companies that treat quality as a system, not a checklist. Those who combine technology, accountability, and transparency. Those who understand that cheap manufacturing today means dangerous products tomorrow. The data doesn’t lie. In 2024, foreign facilities produced 43% of U.S. drugs but caused 62% of recalls. That’s not bad luck. That’s a broken model. Fixing it won’t be easy. But continuing as you are? That’s riskier than ever.What Happens If You Do Nothing?

You might get lucky for a while. One batch passes. Then another. But the odds are stacked against you. A single quality failure can cost millions. A pattern of failures can get your brand blacklisted by retailers. In the worst case, someone gets hurt. And when that happens, it’s not the factory that gets sued-it’s you. The FDA doesn’t care if you didn’t know. They don’t care if you thought your supplier was reliable. They only care if your product reached the patient. And if it didn’t meet standards? You’re on the hook. There’s no shortcut. No quick fix. Just hard work, better systems, and the willingness to pay more upfront to avoid disaster later.Why are quality problems worse in foreign manufacturing now than five years ago?

Profit pressures have pushed many factories to cut corners, and some have shifted from simple mistakes to deliberate fraud-like material substitution and falsified documents. With economic strain growing, financially stressed suppliers are using sophisticated scams to survive, making quality failures more dangerous and harder to detect. The FDA’s past reliance on announced inspections gave factories time to hide problems, and that system is now collapsing under its own flaws.

Can AI really fix quality control in overseas factories?

AI can detect defects with 99.2% accuracy-far better than human inspectors, who average 85-90%. But AI only works if it’s installed and used. Right now, only 22% of Chinese factories have integrated AI systems. The technology isn’t the problem. The adoption is. Companies that use AI for real-time visual inspection, combined with blockchain traceability, are seeing defect rates drop by over 90%.

Is it safer to manufacture in the U.S. or Europe?

U.S. and EU facilities have stricter enforcement and more consistent inspections. The EU’s Qualified Person system requires a licensed professional to sign off on every batch-making them personally liable for quality. U.S. facilities also face random, unannounced FDA inspections. Foreign facilities, especially in China and India, still have higher failure rates. But even domestic manufacturing isn’t foolproof-quality depends on culture and systems, not just geography.

How do I know if my overseas supplier is trustworthy?

Don’t rely on certifications alone. Ask for three references from past clients-and call them. Demand access to their quality logs and raw material certificates. Require a site visit with no advance notice. Hire a local quality manager who reports directly to you. If the supplier resists any of this, they’re hiding something. Trust is earned through transparency, not promises.

What’s the most common mistake companies make with overseas manufacturing?

Assuming that because a factory passed a single audit, they’re reliable. Quality isn’t a one-time check-it’s an ongoing system. The biggest failures happen when companies stop monitoring after the first order. A factory might clean up for an audit, then slip back into old habits. Continuous oversight, unannounced checks, and real-time data are the only ways to stay safe.

Should I stop manufacturing overseas altogether?

Not necessarily. Overseas manufacturing can still be cost-effective-if done right. The issue isn’t location, it’s control. Companies that invest in strong systems, local oversight, and technology are thriving. Those who treat it as a cost-cutting exercise are failing. The goal isn’t to avoid overseas production-it’s to manage it like a high-stakes operation, not a transaction.

Peter Axelberg

November 30, 2025 AT 01:06Let’s be real - we’ve been outsourcing quality control for decades and now we’re shocked when the house catches fire? The whole system was built on blind faith and cheap labor. Factories aren’t evil - they’re responding to incentives. If your contract pays $0.02 per unit and you’re expected to turn out 50,000 a day, you’re not going to spend $500 on proper sterilization. The problem isn’t overseas manufacturing - it’s American companies treating supply chains like disposable diapers.

And don’t get me started on ‘friend-shoring.’ Mexico? Great. But if your quality manager doesn’t speak Spanish and has never stepped foot in a factory, you’re just moving the problem to a new timezone. Real change means putting skin in the game - not just signing a contract and hoping for the best.

We need to stop pretending this is a technical fix. It’s cultural. It’s structural. It’s about who holds the power - and right now, it’s the factory, not the buyer.

Brandy Johnson

December 1, 2025 AT 18:41This is a national security crisis disguised as a supply chain issue. The FDA’s new parity inspections are long overdue, but they’re still reactive. We should be banning imports from any facility that has ever falsified a test result - permanently. No second chances. No ‘we’ll monitor them now.’ If a factory in Wuhan substitutes plastic for silicone in a breathing device, they’ve committed assault. And we’re treating it like a traffic violation.

Meanwhile, our own regulatory agencies are still stuck in 2010. AI is here. Blockchain is here. Real-time monitoring is here. But instead of mandating it, we’re asking nicely. That’s not oversight - that’s negligence. Someone needs to go to jail for this. Not a fine. Not a warning. Jail.

Monica Lindsey

December 2, 2025 AT 15:16Of course it’s worse. Because now the ‘cheap’ factories aren’t just cutting corners - they’re lying. And we’re still surprised? We gave them decades to prove they could be trusted. They didn’t. Now we’re shocked they’re still in business? The real tragedy is that we kept buying from them because we didn’t want to pay $2 more for a toy. We’re not victims. We’re accomplices.

linda wood

December 4, 2025 AT 03:15So let me get this straight - we’re supposed to trust a factory in China that has a ‘showroom’ room just for inspectors? And we’re surprised when kids get sick from toys? Wow. Just wow. I mean, I get it - we want the $5 phone case. But at what point do we stop pretending we’re not complicit in this circus? The answer: yesterday.

gerardo beaudoin

December 4, 2025 AT 16:41I’ve worked with factories in Vietnam and India. The good ones? They’re amazing. Clean, precise, responsive. The bad ones? They’re nightmares. But here’s the thing - most of the bad ones are the ones that get chosen because they’re the cheapest. Companies don’t want to pay for quality. They want to pay for ‘good enough.’

The fix isn’t complicated: hire a local person, pay them well, give them real authority, and let them report directly to HQ. No middlemen. No ‘we’ll check in every quarter.’ Real oversight. It costs more upfront, but you’ll save 10x in recalls and lawsuits. It’s not magic. It’s basic management.

Sullivan Lauer

December 6, 2025 AT 00:55Let me tell you what’s really happening - it’s not just about fraud. It’s about desperation. Factories in China and India are under insane pressure. Their workers are overworked, underpaid, and terrified of losing their jobs. When you’re told to produce 10,000 units a day and your boss says ‘don’t worry about the coating thickness,’ you do it - because you need to feed your family.

So yes, they cheat. But they’re not monsters. They’re people trapped in a broken system. The solution isn’t to punish them - it’s to fix the system. Pay more. Demand less. Build relationships. Treat suppliers like partners, not vendors. That’s how you get real quality. Not AI. Not blockchain. Not audits. Trust.

Peter Lubem Ause

December 8, 2025 AT 00:01As someone from Nigeria who has watched global manufacturing evolve, I can tell you this: the problem is not that factories abroad are bad - it’s that Western companies treat them like disposable tools. We’ve created a race to the bottom where the only metric that matters is cost per unit. No one cares about the person who assembled the device. No one cares about the environment they work in. No one cares if the child who used the toy got sick.

But here’s the truth: quality isn’t a cost. It’s an investment. And the most successful companies I’ve seen - whether in Lagos or Louisville - are the ones who invest in people, not just machines. Hire local experts. Train them. Empower them. Pay them fairly. And then - and only then - will the quality follow.

It’s not about geography. It’s about dignity.

Joy Aniekwe

December 8, 2025 AT 18:44Oh, so now we’re surprised that factories lie when we give them a month to clean up before an inspection? Shocking. Like, who could’ve predicted that? Maybe if we stopped pretending we’re ‘helping’ developing nations and started treating them like equals - instead of cash cows - we’d get better results. But no, let’s keep outsourcing our ethics and then acting like victims when someone gets poisoned by a $3 pacifier.

Sohini Majumder

December 10, 2025 AT 17:48Okay but like… why are we even still doing this?? Like, I get it - money. But like, if your baby’s medicine has impurities because some factory in Bangalore skipped a step… like… what are we even doing with our lives??

And don’t even get me started on ‘friend-shoring’ - like, Mexico?? Are you kidding me?? They don’t even have the same FDA standards!!

And AI?? Bro. AI can’t fix a culture of corruption. You can’t scan your way out of moral bankruptcy.

Also, I think we should just ban all overseas manufacturing. Like, now. Today. I’m done.

tushar makwana

December 11, 2025 AT 01:24Actually, I think we’re looking at this wrong. It’s not about China or India or Vietnam. It’s about how we treat people. In my village in India, we have a small factory that makes medical gloves. They don’t use AI. They don’t use blockchain. But they have a manager who eats lunch with the workers every day. He knows their names. He knows their kids. And when a batch is off, he stops production - even if it means losing money.

That’s the difference. Not tech. Not audits. Just respect.

Maybe if we stopped treating workers like machines, we wouldn’t need AI to catch their mistakes.

Richard Thomas

December 11, 2025 AT 14:53It is beyond comprehension that regulatory bodies continue to permit the importation of pharmaceuticals from jurisdictions where documented instances of material substitution and falsified documentation are endemic. The statistical disparity in recall rates - 62% of U.S. drug recalls attributable to foreign facilities despite accounting for only 43% of production - constitutes a systemic failure of oversight that borders on criminal negligence.

The proposed parity inspection model is a necessary but insufficient corrective. A more robust framework must include mandatory, real-time, blockchain-verified traceability for all critical components, coupled with civil and criminal liability for corporate officers who knowingly engage in supply chain obfuscation. Until such measures are enacted, any assertion of consumer safety is merely performative.

Matthew Higgins

December 11, 2025 AT 16:25I’ve been in this game for 20 years. I’ve seen factories in China, India, Mexico, Poland. Some are clean. Some are dirty. The difference? The ones that work well? They have someone on the ground who actually gives a damn. Not a third-party auditor. Not a compliance officer in Ohio. Someone who lives there, eats there, and can walk into the factory at 3 a.m. and say ‘stop.’

That’s it. No fancy tech. No magic. Just a person who has skin in the game.

And yeah, it costs more. But so does burying a kid because your toy had lead paint. So choose.

Latika Gupta

December 12, 2025 AT 05:58Can someone explain why we keep trusting factories that have lied before? Like, if a company got caught replacing silicone with plastic, why are they still getting contracts? Is there a ‘second chance’ clause in the global manufacturing rulebook? Because I’m missing it.

jamie sigler

December 14, 2025 AT 05:55I just… I don’t even know anymore. I buy a pill. I take it. I hope it works. I don’t want to think about who made it or what they cut. I just want to feel better. Why is that too much to ask?